Bottling

Our Meheen bottling technologies help premium brands ramp up bottling production quickly and efficiently. Backed by 25 years of filling experience, Meheen counterpressure systems offer user-friendly operation and long-term dependability.

Custom made, like your beverages

BOTTLE LIKE YOU MEHEEN IT!

Ramp up your bottling quickly and efficiently.

Our filling technologies help premium brands ramp up bottling production affordably and quickly. A Meheen fully-automated, pneumatic powered filler can produce up to 2,160 bottles per hour and help you increase distribution, revenues and profit margins from the first

- Speed Up To: 14 cans per minute (840 cans per hour) based on 100 mL can at optimal product conditions

- Can Size: 100 mL 202 steel can body with 200 lid type

- Dimensions: 44″ L x 26″ W x 41-43″ H (112 cm L x 66 cm W x 104-109 cm H)

- Deck Height: Entry and exit deck height of 12-14″ (30.5-35.5 cm)above base surface

- Standard Configuration: Tabletop system with adjustable leveling feet

- Weight: 275 lb (125 kg)

- Power: Single-phase 13A @ 115VAC, 50/60 Hz or Single-phase 200V-240V

- Air: Clean, dry compressed air required at 6.5 scfm @ 95-100 psi (185 L/min @ 6.2-6.9 bar) in accordance with ISO 8573-1:2010 (-:4:-). Dew Point < 37° F (3° C)

- CO₂: Required at 12-25 PSI (0.8-1.7 bar)

- Warranty: Standard 1-year warranty; Extended warranty available

CE-Certified

COMPATIBLE ACCESSORIES

- Multiflow Control Kit

- DO Buster™ CO2 Tunnel

- Pre- and Post-Rinse

- GooseNeck Infeed™

- Liquid Nitrogen Dosing

- Mobile Cart

- Advanced Tool Kit

- Spare Parts Kit

- SPA Treatment (Service Partnership Agreement)

Resources

Everything you need in one place. Find specification sheets, customer spotlights, videos and a bunch of other stuff in our resources section. Don’t see what you need right here? Find a complete list on the Resources page.

Bottling Accessories

Configuration Options

Don’t limit growth potential with costly bottling machinery upgrades. Using multiple bottling systems in a variety of configurations will meet your bottling needs at a fraction of the cost of a single rotary upgrade.

Spare Parts Kits

A variety of essential components specific to your machine.

Bubble Butler™ Carbonation Management System

Automates accurate carbonation control for your tank to deliver consistent and stable carb levels for your beverage.

What sets Meheen bottling machines apart

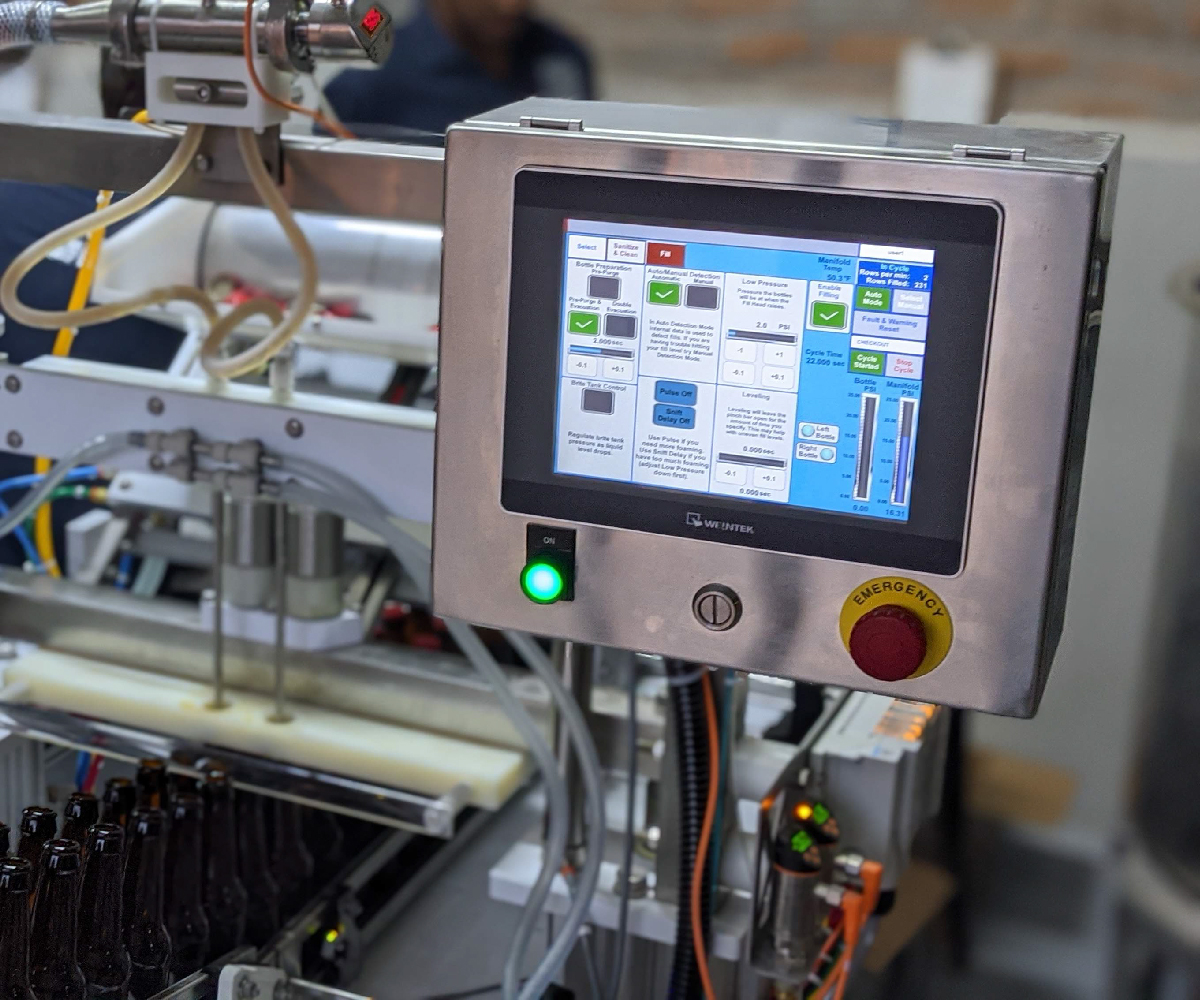

COMPLETE CONTROL

Touch screen technology helps you monitor and control fill rates, counter pressure, CO2 pulse/fobbing and other aspects of your filling process at the touch of a button

CONSISTENT FILLS

Bottle pre-evacuation, pressures and long fill tubes give you consistent pours with low O2 pickup and minimal product loss.

PNUEMATICALLY POWERED

For long term reliability. No motors, gears or bearings to maintain.

SMALL FOOTPRINT

Configurable to grow as you grow. Using multiple Maheens in a variety of configurations will meet your bottling needs at a fraction of the cost of a single rotary upgrade.