Don’t limit growth potential with costly bottling machinery upgrades. Using multiple bottling systems in a variety of configurations will meet your bottling needs at a fraction of the cost of a single rotary upgrade.

BOTTLE LIKE YOU MEHEEN IT!

Ramp up your bottling quickly and efficiently.

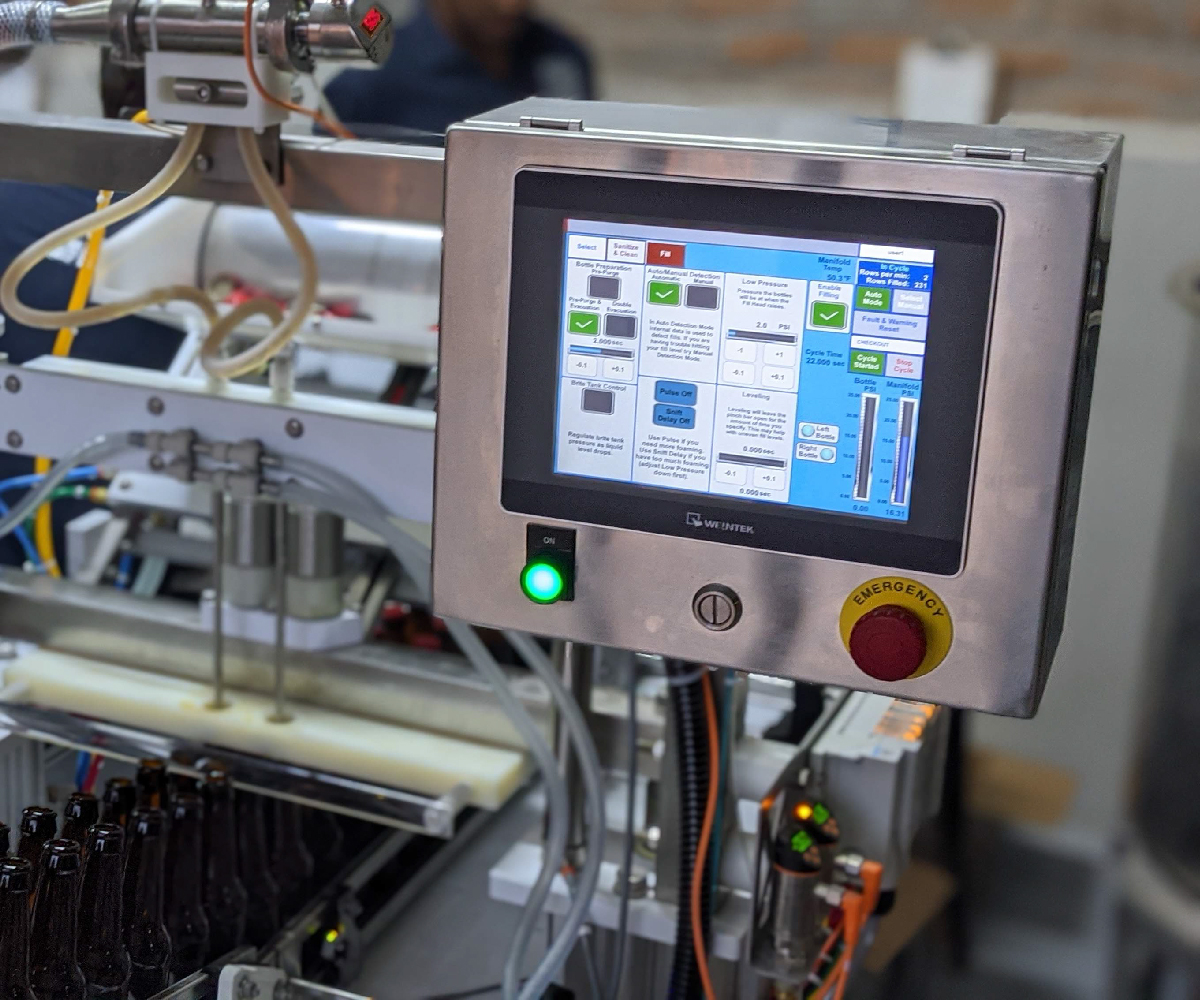

Our filling technologies help premium brands ramp up bottling production affordably and quickly. A Meheen fully-automated, pneumatic powered filler can produce up to 2,160 bottles per hour and help you increase distribution, revenues and profit margins from the first

- Speed Up To: 14 cans per minute (840 cans per hour) based on 100 mL can at optimal product conditions

- Can Size: 100 mL 202 steel can body with 200 lid type

- Dimensions: 44″ L x 26″ W x 41-43″ H (112 cm L x 66 cm W x 104-109 cm H)

- Deck Height: Entry and exit deck height of 12-14″ (30.5-35.5 cm)above base surface

- Standard Configuration: Tabletop system with adjustable leveling feet

- Weight: 275 lb (125 kg)

- Power: Single-phase 13A @ 115VAC, 50/60 Hz or Single-phase 200V-240V

- Air: Clean, dry compressed air required at 6.5 scfm @ 95-100 psi (185 L/min @ 6.2-6.9 bar) in accordance with ISO 8573-1:2010 (-:4:-). Dew Point < 37° F (3° C)

- CO₂: Required at 12-25 PSI (0.8-1.7 bar)

- Warranty: Standard 1-year warranty; Extended warranty available

CE-Certified

COMPATIBLE ACCESSORIES

- Multiflow Control Kit

- DO Buster™ CO2 Tunnel

- Pre- and Post-Rinse

- GooseNeck Infeed™

- Liquid Nitrogen Dosing

- Mobile Cart

- Advanced Tool Kit

- Spare Parts Kit

- SPA Treatment (Service Partnership Agreement)