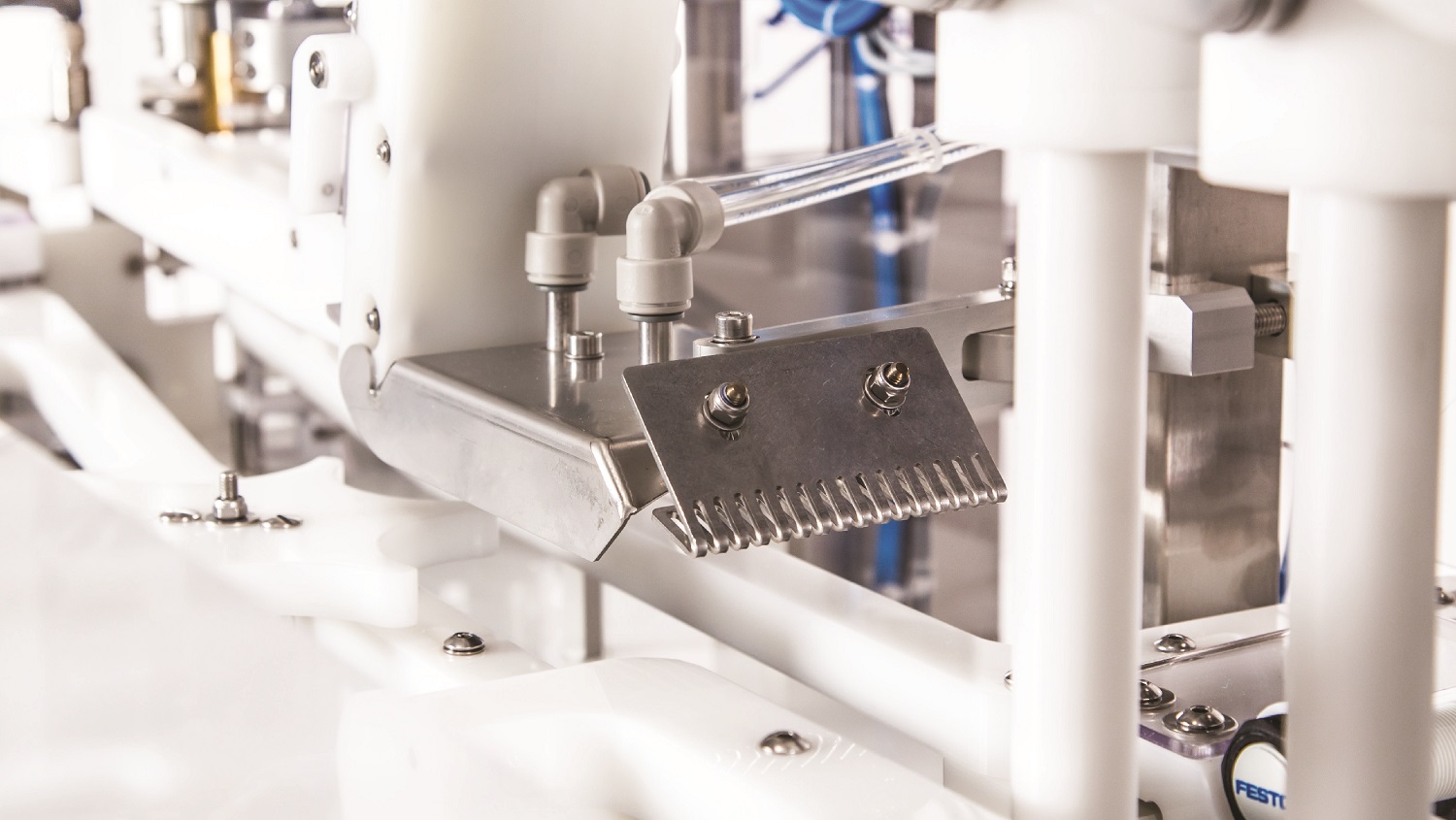

Accommodates a wide range of standard, sleek and slim body cans that utilize 200, 202, 204 and 206 diameter can ends.

UP TO 12 CANS PER MINUTE

Now With An Integrated Control Interface

Gosling 2.0 is an automated, entry-level beverage canning system designed for packaging and maintaining the quality of small product volumes from tank or keg. The system incorporates our patented seaming and filling technology to deliver the same superior consistency as our higher speed machines. With the ability to accommodate multiple can heights and carbonated or non-carbonated beverages, Gosling 2.0 gives you the professional packaging flexibility you need.

Quality craft canning, simplified.

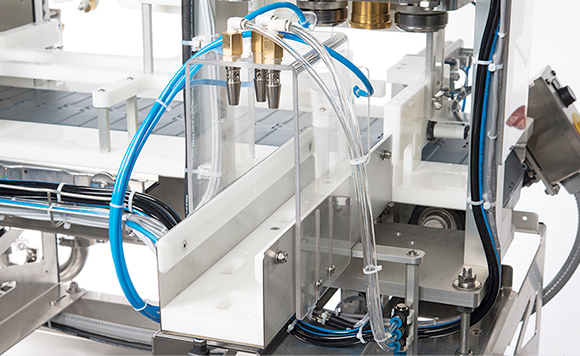

- Automatic counterpressure filling with 2, 4 or 6 fills heads

- Automatic crowning

- Semi-automatic rinsing

- Dimensions: 5.5′ L x 3.5″ W (1.7 m L x 1.1 m W)

- Power: Single-phase 17A @ 115VAC, 50/60 Hz or 9A @ 230VAC, 50/60 Hz

- Air: Clean, dry compressed air required at 15 cfm @ 90 psi (25 m3/h @ 6.2 bar); refrigerated air dryer and coalescing air filter rated to 0.10-0.01 micron required

- CO2: Up to 12 cfm @ 40 psi

- Training: Onsite for 2-3 days

CE-Certified

COMPATIBLE ACCESSORIES

- Adjustable Leveling Feet

- Big Crown Hopper

- Guarding