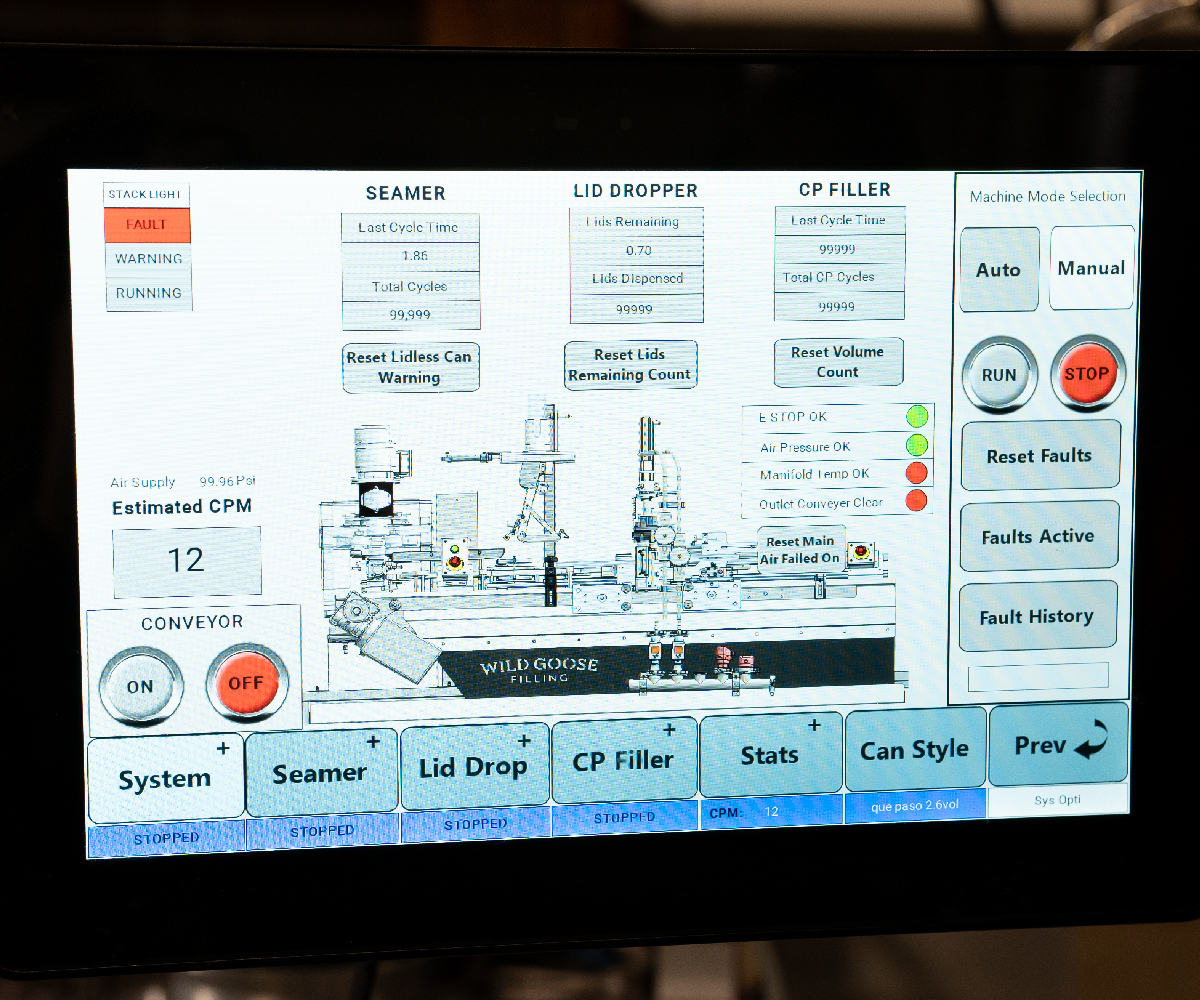

Automate your Wild Goose canning system’s fill consistency over a range of beverage conditions and styles.

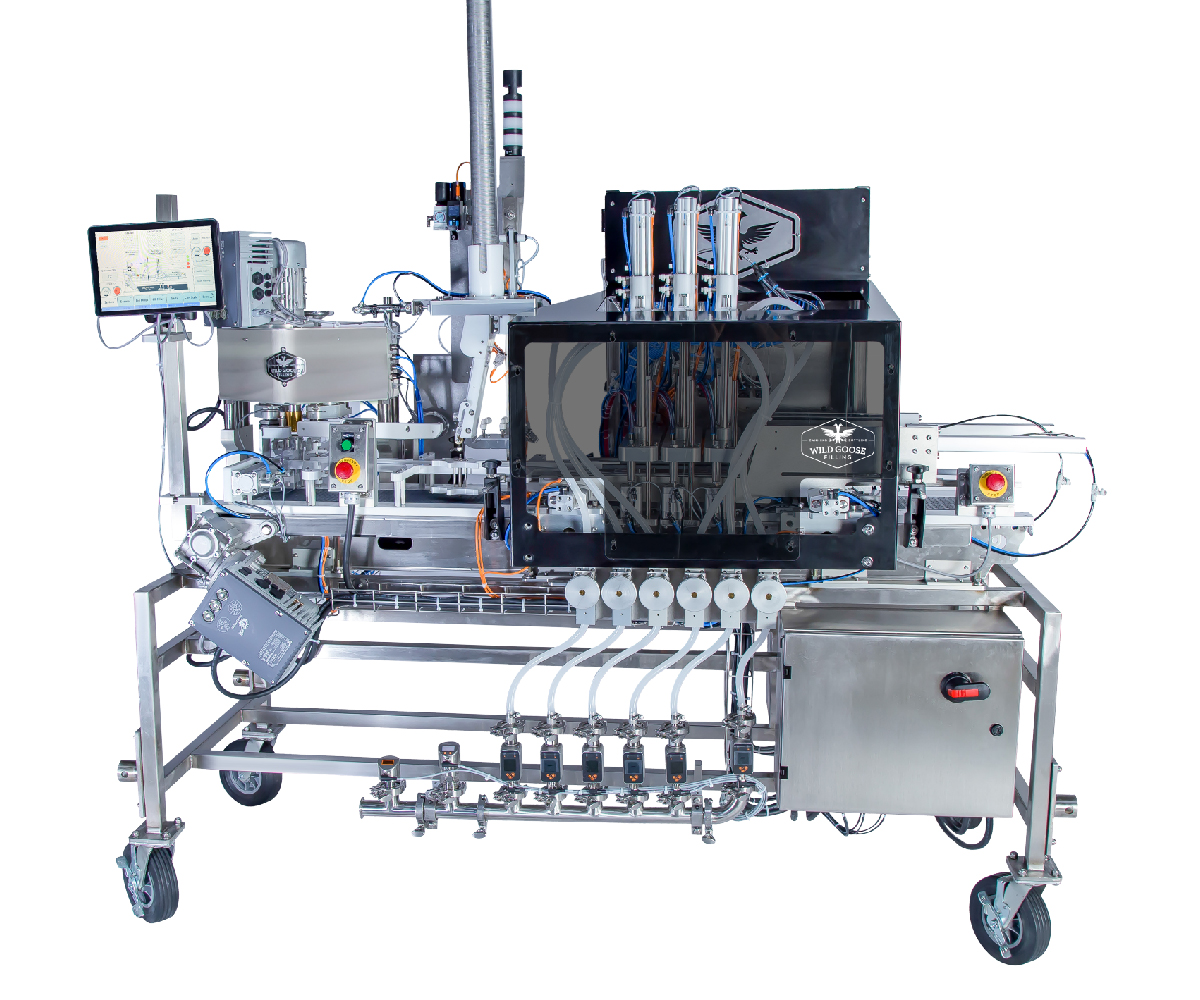

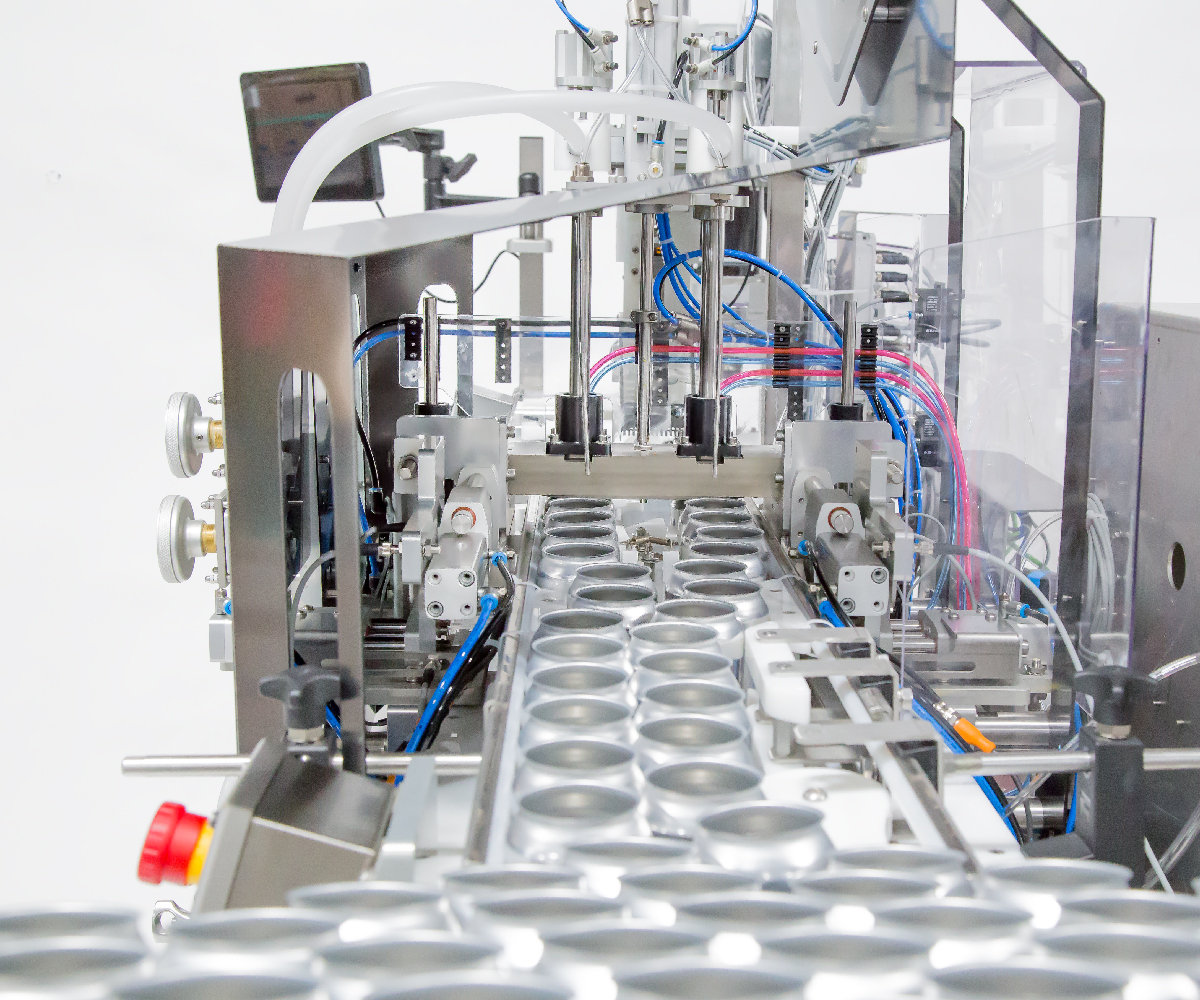

UP TO 45 CANS PER MINUTE

The first canning system with counter pressure + atmospheric filling.

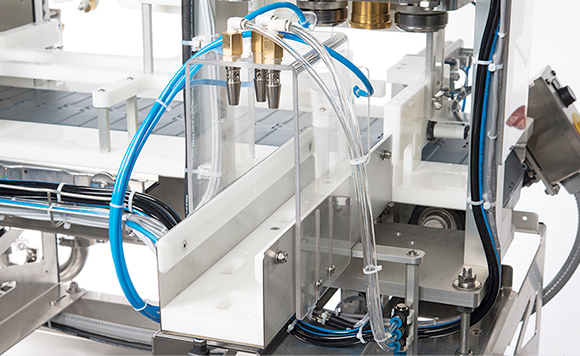

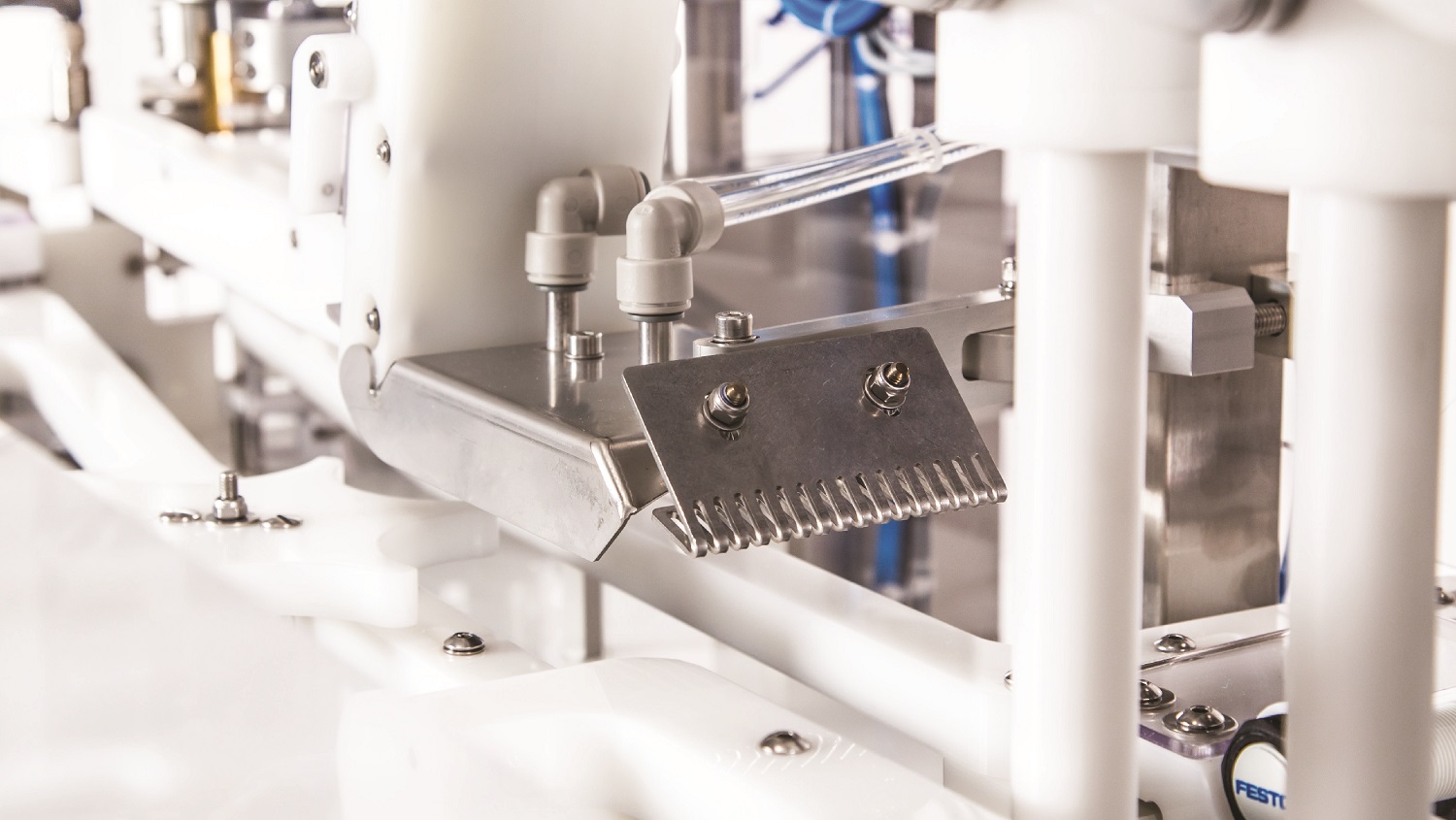

The Wild Goose Fusion™ 2.0 Counter Pressure + Atmospheric Canning System accommodates virtually every craft beverage across a wide range of product conditions, like higher product carbonation levels, pressures and temperatures. Our proprietary system design uses groundbreaking dual counter pressure and atmospheric filling technologies developed by Wild Goose. The Wild Goose Fusion canning line combines the best of our pioneering fast-pour innovations with the versatile bandwidth of pressurized filling to give you unmatched counter pressure canning performance.

- Speed Up To: 14 cans per minute (840 cans per hour) based on 100 mL can at optimal product conditions

- Can Size: 100 mL 202 steel can body with 200 lid type

- Dimensions: 44″ L x 26″ W x 41-43″ H (112 cm L x 66 cm W x 104-109 cm H)

- Deck Height: Entry and exit deck height of 12-14″ (30.5-35.5 cm)above base surface

- Standard Configuration: Tabletop system with adjustable leveling feet

- Weight: 275 lb (125 kg)

- Power: Single-phase 13A @ 115VAC, 50/60 Hz or Single-phase 200V-240V

- Air: Clean, dry compressed air required at 6.5 scfm @ 95-100 psi (185 L/min @ 6.2-6.9 bar) in accordance with ISO 8573-1:2010 (-:4:-). Dew Point < 37° F (3° C)

- CO₂: Required at 12-25 PSI (0.8-1.7 bar)

- Warranty: Standard 1-year warranty; Extended warranty available

CE-Certified

COMPATIBLE ACCESSORIES

- Multiflow Control Kit

- DO Buster™ CO2 Tunnel

- Pre- and Post-Rinse

- GooseNeck Infeed™

- Liquid Nitrogen Dosing

- Mobile Cart

- Advanced Tool Kit

- Spare Parts Kit

- SPA Treatment (Service Partnership Agreement)